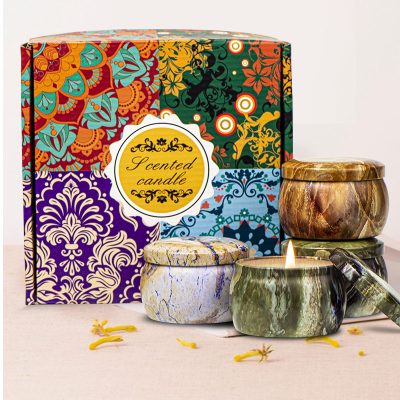

| Item Name | Candle Tins |

| Material | Tin |

| Size | custom size |

| Thickness | 0.23/0.25/0.28/0.3/0.35customized |

| Printing | Customized design |

| Printing Method | CMYK, silk screen, heat transfer etc |

| MOQ | 500 |

| Sample time | (1) 10-15 days after artwork approved

(2) 1-2 days for our existing samples for reference if needed |

| Delivery time | 25-40days; (according to order qty) |

| Audit | TCCC audit, SEDEX 4-Pillar audit, BSCI audit, ISO9001 and so on. |

| Application | home, dinning room, yofa, holiday |

| OEM accepted | Yes and Welcome |

| Packing details | customized |

Metal cans are the so-called pop-top cans, whose lids and cans are produced separately and assembled together at the end. The advantages of this metal can are obvious, its tightness is very good, and it can resist high internal pressure. There are two materials for making cans: aluminum and tinplate. Because aluminum has a high recycling and reuse value, out of consideration for environmental protection, aluminum cans have begun to be used in large quantities.

Aluminum’s strong opponent in the packaging industry comes from PET materials. PET materials can be made into strange shapes through injection molds, but aluminum materials are more difficult. However, there is a big difference in price between the two. PET is affected by oil prices, while aluminum can be recycled and used to reduce material costs.